HISTORY OF AIR SPRINGS

The History of Air Spring Suspension Technology

The origins of airbag suspension technology are not clear, but it was likely developed by multiple individuals and companies in the automotive industry over several decades. Some of the early pioneers in air suspension systems include Chrysler and Firestone, who both introduced air suspension systems in the 1950s. Today, many automotive manufacturers use airbag suspension in their vehicles, including luxury brands like Mercedes-Benz, Audi, and Land Rover.

The use of air suspension in commercial 18-wheelers or tractor-trailers is believed to have started in the 1960s and 1970s, as trucking companies sought to improve the ride comfort and handling of their vehicles. Prior to the adoption of air suspension, leaf springs were the most common suspension system used in commercial trucks. The advent of air suspension allowed for improved load capacity and better ride comfort, making it a popular choice for long-haul trucking. Today, many commercial trucks and trailers use air suspension systems, and the technology continues to evolve to meet the changing needs of the trucking industry.

The development of commercial airsprings, also known as airbags or air suspension systems, likely took place over several decades as a result of ongoing innovation and experimentation in the automotive industry. Early air suspension systems were primitive and unreliable, but as technology advanced and manufacturing processes improved, air suspension systems became more reliable and widespread.

The development of commercial airsprings was likely driven by a number of factors, including the need for improved ride comfort, better load capacity, and increased safety in commercial vehicles. Automotive engineers and manufacturers likely experimented with different designs and materials until they arrived at a commercially viable air suspension system that met the needs of the trucking industry.

Today, commercial airsprings are an essential component of many commercial vehicles, including trucks, buses, and trailers, and they continue to evolve to meet the changing needs of the transportation industry.

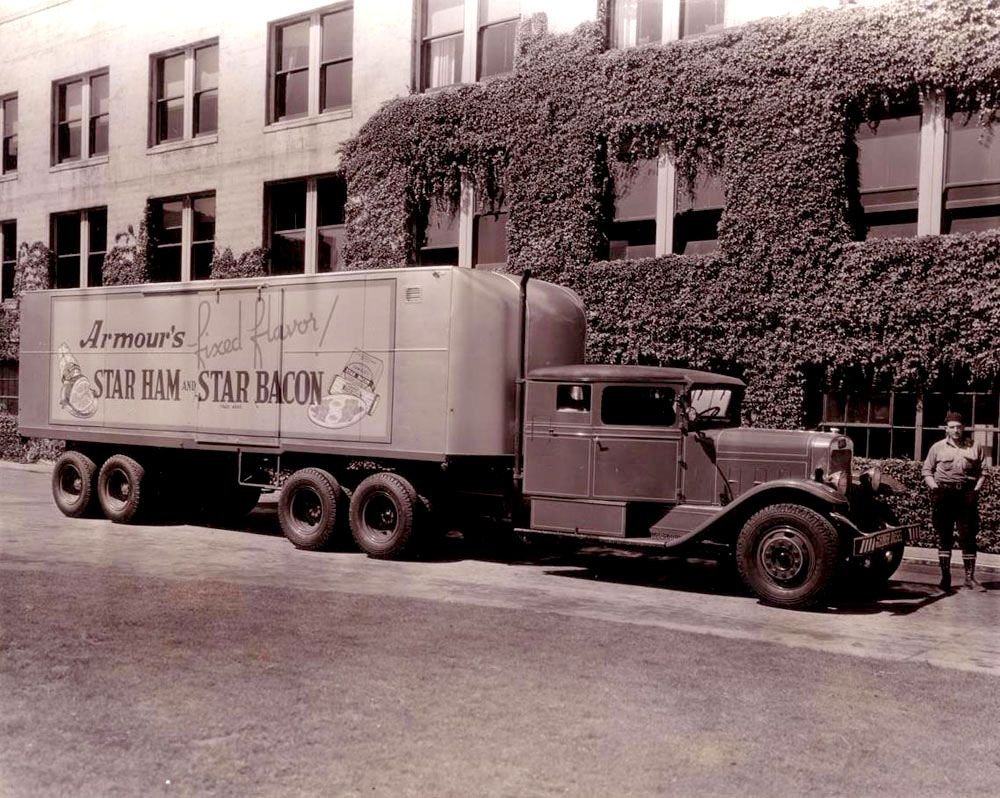

The history of 18-wheelers, also known as tractor-trailers, can be traced back to the early 20th century when the advent of the automobile led to a boom in the trucking industry. The first tractor-trailers were designed in the 1910s, but they did not become widely used until after World War II, when improvements in highways and the expansion of the trucking industry made long-haul trucking a viable mode of transportation.

In the early years, tractor-trailers were limited by the weight they could carry, but as the trucking industry grew, so did the size and capacity of tractor-trailers. Over the decades, advances in technology and design have resulted in larger and more efficient tractor-trailers that are capable of carrying massive loads across long distances.

Today, tractor-trailers play a critical role in the global economy, transporting goods and materials across the country and around the world. The 18-wheeler has become a symbol of the trucking industry and a ubiquitous sight on highways and roads everywhere. Despite the challenges posed by changing regulations and economic conditions, the tractor-trailer remains a key component of the transportation landscape, serving as the backbone of the world's supply chains.

The adoption of air spring suspension in the trucking industry brought several significant benefits and changed the industry in several ways. Some of the key ways air spring suspension has impacted the trucking industry include:

Improved ride comfort: Air spring suspension systems provide a smoother and more comfortable ride for the driver, reducing driver fatigue and improving safety on the road.

Increased load capacity: Air suspension systems are more flexible and capable of carrying heavier loads than traditional spring suspension systems, allowing trucking companies to carry more cargo and increase their efficiency.

Enhanced safety: Air suspension systems can be designed with safety features such as automatic leveling, which helps to maintain stability and prevent rollovers, and air dump valves, which can quickly reduce the air pressure in the suspension in an emergency situation.

Increased efficiency: Air suspension systems are lighter and more efficient than traditional spring suspension systems, allowing trucks to carry more weight while consuming less fuel.

Adaptability: Air suspension systems can be adjusted to accommodate different loads and driving conditions, providing greater flexibility for trucking companies and helping to meet the changing needs of the industry.

Overall, the introduction of air spring suspension in the trucking industry helped to improve ride comfort, safety, efficiency, and adaptability, making it an essential component of modern trucking operations.